Top organization for training seekers around Weinheim

For several years now, the Weinheim Training Day, or WHAT for short, has been one of the most important points of contact for students and other groups interested in training in Weinheim and the surrounding region. The Weinheim Town Hall, with its air-conditioned interior, offers an excellent setting for finding out about career opportunities in a pleasant atmosphere, even in summer. The now experienced organization team makes it a pleasure for exhibitors and visitors alike to meet in Weinheim and talk about training opportunities. From the very beginning, the comprehensive concept of WHAT has also included the so-called “online fair.” Here, companies have the opportunity to present information about their career opportunities to those who were unable to make it to the training fair at the Weinheim City Hall. PAPUREX was also represented with an online booth again this year.

PAPUREX has been a regular guest at the training fair for years.

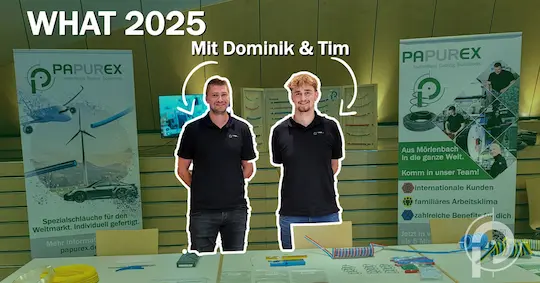

WHAT 2025 took place on July 4, 2025, as described above. From PAPUREX’s perspective, this year’s fair was once again a complete success. After 2023 and 2024, our team was there for the third year in a row. That alone speaks for itself. More than 50 companies from a wide range of sectors, including public service, education, retail, media, and, of course, skilled trades, presented their training opportunities at the city hall. In addition to regional providers of training places, supraregional corporations were also present. This extensive range of opportunities attracts numerous people interested in training to WHAT every year. Many schools in the region also organize trips to the training day to give their students the opportunity to find out about career opportunities from the exhibiting companies. The PAPUREX representatives, in the person of our HR development project manager Dominik and our trainee industrial clerk Tim, were able to hold numerous interesting discussions about career opportunities at PAPUREX and the future plans of young people from a wide variety of backgrounds.

Training in a wide range of areas

PAPUREX flies the flag for skilled trades in the plastics processing industry. With our plastics technology training program, we offer the opportunity to learn the craft of extrusion from the ground up. After completing their training, our skilled workers are then able to manufacture over 6,000 different product variations in the field of industrial hoses in all their facets. A true classic of the craft is also represented in the PAPUREX training program: training as a mechatronics engineer. For those interested in training who are less skilled with their hands, we also presented the training occupation of industrial clerk at WHAT.

After WHAT 2025, one thing is already certain for us: next year, we will once again be represented on site in addition to our online exhibition stand to present our training opportunities in Weinheim. The date has already been set: Wednesday, June 17, 2026 – save the date!