Brief overview of tubing diameters

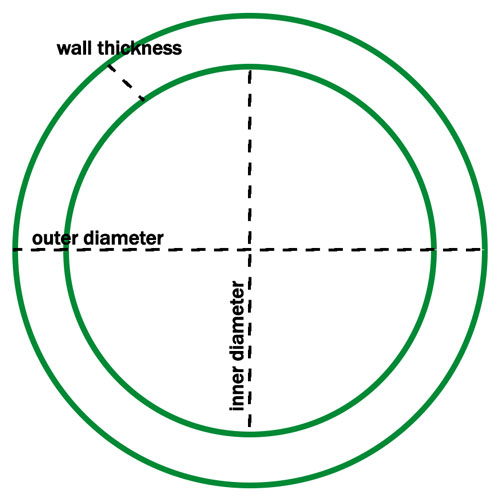

The diameter of a tube is decisive for its subsequent application. A distinction must be made between the inner diameter and the outer diameter. The outer diameter indicates the length of the entire cross-section of a tube, including the wall. This is particularly important for estimating how much space the tube will take up during subsequent installation. In addition, the outer diameter determines how much leeway there is for the wall thickness and inner diameter of a tubing.

The inner diameter of a tube is calculated by subtracting twice the wall thickness from its outer diameter. Simply put, it indicates how big the “hole” in the tube is. This tubing diameter determines how much flow can ultimately be generated. Maximizing the inner diameter increases the flow. However, this leads to a decrease in wall thickness, which in turn leads to lower stability. The same applies vice versa. If you want to increase the stability of the tube, the wall thickness increases and the inner diameter (with the same outer diameter) inevitably decreases.

The following graphic illustrates the different tubing diameters and wall thicknesses.

Extreme diameters are difficult to extrude

Extrusion is a process technology that, when understood as a craft, enables an enormous variety of products. For example, PAPUREX’s largest tube with an outer diameter of 28 mm, the V:S:S®, is produced by extrusion, as is a 3 mm tube based on polyester polyurethane.

Both ends of the range have their own challenges. One thing is certain: in order to produce tubing of appealing quality that approach these thresholds with their tubing diameter, expertise is essential.

PAPUREX pushes the boundaries of tubing diameter

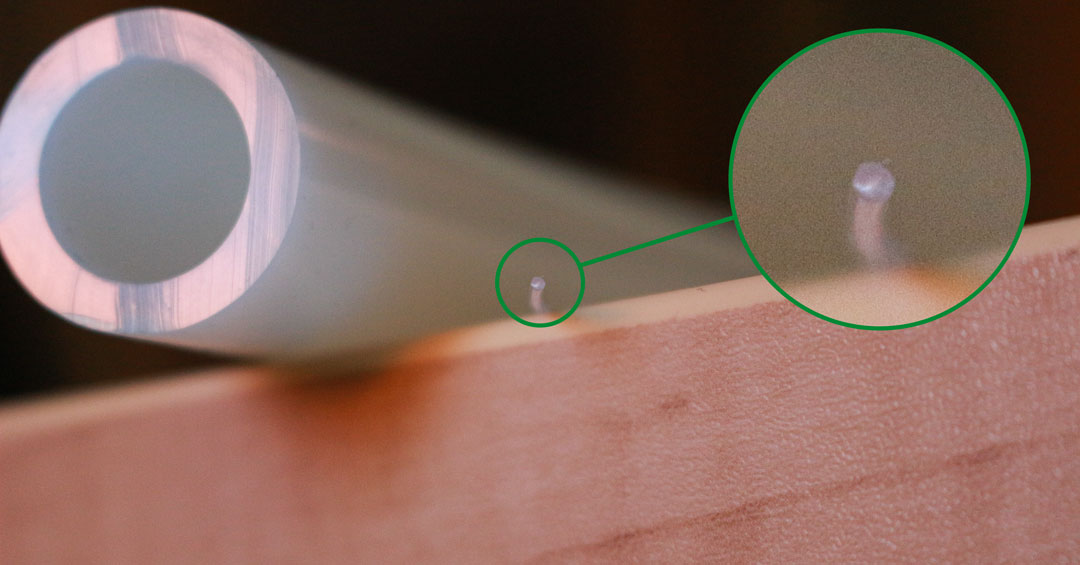

True to its motto of “Individual Tubing Solutions,” the product development team at the Odenwald-based tubing manufacturer has pushed these boundaries. As mentioned above, the previous lower limit for the smallest tubing diameter produced was 3 mm. In response to a customer request, this mark has now been significantly exceeded in a trial.

The developers have succeeded in producing a round cord with an outer diameter of less than 1 mm. This is more than 43 times smaller than the largest tube in the PAPUREX range. Technically speaking, a round cord is no longer a tube, as the customer requested a cord made of solid material. This meant that the “hole” in the middle, which makes a round cord a tubing, was missing.

Nevertheless, the performance of the production colleagues involved cannot be praised highly enough. The machines, which are designed for completely different dimensions and material quantities, also reached their limits in the attempt to produce the smallest extrudate in PAPUREX’s history. It is not without reason that the tubing diameter range for most manufacturers only starts at 4 mm (and often ends at 16 mm).

Customer inquiry from an unusual sector

Most PAPUREX customers can be classified as belonging to sectors such as the automotive industry, mechanical engineering, or industrial wholesale. However, the inquiry that led to the smallest tubing diameter in the company’s history came from a completely different sector: the music industry. The potential customer is looking for an alternative material for the manufacture of guitar strings. Polyurethane is also an option, which is how they became aware of PAPUREX.

Do you also have an unusual project? Then get in touch today (contact). Our experts will be happy to advise you!