Tubing diameter – interesting facts about this parameter

Definitions, units, measuring correctlyTubing diameter – a compact overview of the topic:

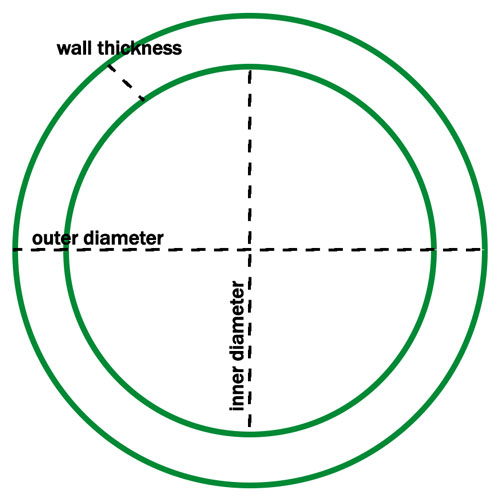

The tubing diameter describes the size of a tubing and is determined by the inner and outer diameter as well as the wall thickness. While the inner diameter influences the flow rate and thus the delivery rate, the outer diameter is decisive for installation, space requirements, and compatibility with connectors. In addition to common tubing sizes, this article also explains how tubing diameters can be calculated, measured, and converted into different units (mm/inches). It also explains tolerances, which play an important role in the fit and pressure resistance of technical tubing.

Definitions of inner and outer diameter

In order to determine the correct tubing diameter for your application, you first need to clarify which diameter is decisive. With tubing, a distinction is made between the inner diameter and the outer diameter.

The inner diameter is particularly important when a certain volume of a medium (e.g., air or water) has to be conveyed through the tubing. In this case, we refer to the flow rate that the tubing can guarantee. As the name suggests, the inner diameter refers to the size of the interior of a tube. Simply put, the inner diameter indicates how large the “hole” in the tubing is. It can be calculated if the wall thickness and outer diameter of the tubing are known:

- Inner diameter = outer diameter – wall thickness × 2

The outer diameter, on the other hand, indicates the overall dimensions of tubing. This refers to the cross-section of tubing, which includes both the inner diameter and the wall. This tubing diameter is particularly important when determining whether there is sufficient space to install tubing or whether the tubing will fit into a connector. The outer diameter can also be calculated if the inner diameter and wall thickness of the tubing are already known:

- Outer diameter = inner diameter + wall thickness × 2

The inner diameter can be maximized for the same outer diameter by reducing the wall thickness. This even has a cost advantage because less material is required for production. However, this also has a significant disadvantage. The wall thickness contributes significantly to the pressure resistance of the tubing. The wall should therefore always be as thin as possible, but as thick as necessary. You can find more information on the pricing of polyurethane tubing and pressure resistance (burst pressure vs. working pressure) in our corresponding articles. With the right knowledge about tubing diameter, you can maximize flow, minimize costs, and ensure the desired pressure resistance.

What tubing diameters are available?

In the field of extruded polyurethane tubing, the smallest tubing diameters, in terms of outer diameter, start at 3 mm. An example of this is the classic pneumatic tubing based on polyester polyurethane. This tubing has an inner diameter of 1.8 mm. Conversely, the wall thickness in this case is 0.6 mm. However, the smallest extrudate in the history of PAPUREX did not even have a tubing diameter of one millimeter. However, this was only an experiment. The largest tubing diameter produced by the tubing manufacturer PAPUREX is 28 mm (outer diameter). This is the case with the V:S:S® supply system tube.

There is no general answer to the question of what standard tubing diameters are available. This depends on a number of factors, such as the intended use. But even within a single area of application, such as pneumatics, there are differences. If, for example, different materials are used in production, a different wall thickness may be required to achieve the same pressure resistance. The inner diameter, therefore, varies. The Shore hardness of the material used plays a decisive role here. As a result, the following table only displays the common tubing diameters for pneumatic tubing based on polyether or polyester polyurethane.

| Outer diameter [mm] | Inner diameter [mm] Polyester-Polyurethane | Inner diameter [mm] Polyether-Polyurethane |

| 3 | 1,8 | Not common |

| 4 | 2,5 | 2,5 |

| 4,3 | 2,85 | Not common |

| 5 | 3,1 | Not common |

| 6 | 3,9 | 3,9 |

| 8 | 5,7 | 5,5 |

| 10 | 7,5 | 7 |

| 12 | 9 | 8 |

| 14 | 11 | 10 |

| 16 | 11 | 11 |

However, the standard shown in this table is by no means the limit of what is possible. PAPUREX is able to manufacture all conceivable tubing diameters between a few millimeters and up to 28 mm outer diameter. Do you have a very specific combination of inner diameter and outer diameter in mind? No problem, the team of experts at PAPUREX will be happy to advise you!

Tolerances for tubing diameters

Tubing diameters must be very precise, depending on the industry. There is a huge difference between garden tubing and industrial tubing. The former have significantly larger tolerance ranges, as their application requires less precise dimensions. In general, tolerance describes a margin for manufacturing within which a part may deviate from the nominal dimension. For example, if the nominal dimension (outer diameter) of tubing is 8 mm and the tolerance is – 0.1/+0.05 mm, then dimensions from 7.9 mm to 8.05 mm are acceptable.

Tolerances on tubing diameters are an essential part of choosing the right tubing. Minimal dimensional deviations are unavoidable in manufacturing processes such as extrusion. This makes it all the more important to determine in advance in which directions these deviations can be steered. When it comes to tubing for industrial use, a distinction must be made between tubing with internal tolerances and tubing with external tolerances.

Internally tolerated tubing

For internally tolerated tubing, the tolerance is applied to the inner diameter of the tubing. This is particularly useful if the tubing has to guarantee a certain flow rate. An additional application for internally tolerated tubing is when the tubing is connected to a tubing connector. The internal tolerance ensures that the tubing is not too loose (if it were too large) and that it is not damaged when pushed on or does not fit at all (if it were too small).

Externally tolerated tubing

With externally tolerated tubing, on the other hand, the tolerance is applied to the outer diameter. This is particularly useful when working with plug connectors. In this case, the tubing is inserted into a tubing connector for connection. The external tolerance ensures that the tubing fits into the connector (is not too large) but at the same time does not sit too loosely (is not too small). The type of tubing connector used, therefore, has a decisive influence on the choice of tolerance. An external tolerance also makes sense if there is only limited space available for laying the tubing. This is the case, for example, when inserting it into cable ducts. If the tubing diameter is too large here, this can lead to considerable problems during installation.

Measuring tubing diameter correctly

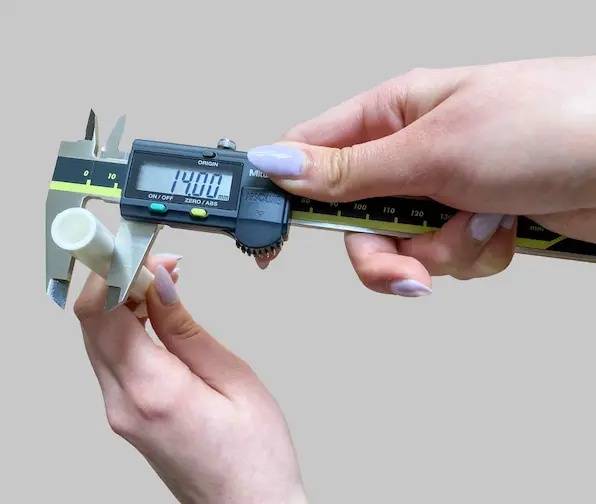

When measuring tubing diameter, there are certain basic rules to follow. Ideally, the inner diameter should be measured using a suitable measuring mandrel. To do this, slide the tubing onto the measuring mandrel. If it fits as tightly as desired, the correct inner diameter has been achieved. If it is very difficult or impossible to slide onto the mandrel, the inner diameter of the tube is too small. If it fits very loosely on the measuring mandrel or does not fit at all, the inner diameter is too large. This method has several advantages over measuring with a caliper gauge:

- Avoid deformation: A caliper gauge can deform soft materials depending on the pressure applied, thereby distorting the results.

- Reproducibility: Inserting the measuring mandrel to the desired resistance is relatively easy to reproduce.

- Very small tubing diameters: For very small tubing with a diameter of only a few millimeters, many calipers are simply too large to be used for measurement.

- Quick pass/fail test: The measuring pin can be used to quickly determine whether the tube is within or outside the desired tolerance.

The outer diameter of tubing is best measured using a combination of a caliper gauge and a measuring mandrel. If only the caliper gauge is used, there is a risk that the material will be deformed by the pressure exerted, as is the case when measuring the inner diameter. If the pressure is not kept constant, this can lead to deviations in the result. To minimize deformation of the tubing during the measurement process, it can be pushed onto a suitable measuring mandrel beforehand. This prevents the walls of the tubing from being pushed together and the outer diameter from being distorted.

Units for tubing diameter

Although the metric system is used in most countries worldwide, tubing sizes are still specified in inches in many industries. However, the inch is a unit of the imperial system. There are many reasons for this. One reason is that the first standards for pipes and threads were developed in England in the 19th century and defined in inches. In many places around the world, these original standards were retained out of habit because entire systems were designed around them. To ensure global compatibility, some regions have adapted to this, even though metric units are otherwise preferred. This often also applies to the unit specified for tubing diameter. The following tool simplifies the conversion from inches to millimeters and vice versa.

Frequently asked questions (FAQ) about tubing diameter

What does DN in the context of tubing diameter mean?

What diameter does a 1/2 inch tube have?

What tubing diameters are available?

How can I calculate tubing diameter?

-

Inner diameter = outer diameter – wall thickness x 2

-

Outer diameter = inner diameter + wall thickness x 2

How do I measure the tubing diameter correctly?

Any questions?

Don’t hesitate to give us a call – we are happy to advise you.