Tubing connectors for all applications – an overview

Areas of application, materials, forms and more.Last updated on January 22, 2026

Tubing connectors are an essential component of piping systems. If the wrong one is used, the connecting elements quickly become the predetermined breaking point. This overview summarizes everything you need to know to find the right tubing connectors for all applications. This ultimately saves time, money, and, above all, stress. The following topics are covered:

Areas of application for tubing connectors

Tubing connectors in pneumatics

Pneumatic tubing conveys compressed air from one point to another to perform work. In most cases, a relatively low pressure of between 2 and 10 bar is sufficient. Depending on the source, this pressure range is referred to as “normal pressure” or “low pressure.” As a result, tubing connectors in pneumatics must above all be easy to handle and install. Enormous pressure stability is only important in exceptional cases. Nevertheless, it should be noted that installation must lead to absolutely tight results despite quick handling. The gold standard for this are so-called plug-in connectors, into which the tubes, as the name suggests, simply have to be inserted. The basic requirement for this are externally tolerated tubes that can be inserted precisely into the plug-in connection. Alternative tubing connectors, which additionally use tube clamps, can withstand higher loads in some cases but are more complex to install.

Tubing connectors in hydraulics

Hydraulics is always referred to when fluids are pressurized to perform work. In most cases, these are mineral oils. The pressure ranges in hydraulics are significantly higher than those commonly found in pneumatics. In the context of hydraulics, applications up to 100 bar are referred to as low pressure. The medium pressure range is defined as 100 to 200 bar, while applications above this fall into the high-pressure range. Even pressures of up to 600 bar are commonplace here. Accordingly, stability plays an important role in hydraulic tubing connectors. Connectors with screw connections are often used here, which are significantly more complex to install than simple plug connectors, but ensure higher pressure stability.

Tubing connectors in supply engineering

Unlike those used in pneumatics and hydraulics, some piping systems are not intended for performing work tasks but purely for supplying media (gases, liquids, granulates, etc.). In this case, pressure usually plays a completely subordinate role. However, tubing connectors in media technology must be suitable for the respective application. For example, a tube connector used for water pipes should be resistant to hydrolysis (dissolution by water). In addition, many chemicals that flow through supply engineering pipes attack tubes and tubing connectors, which is why particular attention must be paid to chemical resistance in this area.

Types of tubing connectors

Plug connectors – when speed counts

The main advantage of plug connectors is that they save a lot of time. Most plug connection systems can be installed without special tools. As the name suggests, with this type of tube connector, the tube is simply inserted into the connection. However, to ensure that the system is sufficiently tight, precisely calibrated tubes and precisely manufactured connectors are required. If the dimensions of the tube and connector do not match exactly, the risk of leakage increases. Just as most push-in connectors can be installed without tools, they can also be quickly removed without additional tools. This offers the advantage that maintenance can be carried out without great effort. In addition, an existing pipe system with plug connectors can be expanded or modified in this way without great effort.

Screw connectors – for high mechanical loads

Screw connectors, sometimes also called screw connections or threaded connectors, are very robust tubing connectors. Their biggest advantage over plug connectors is that they can withstand higher pressures, as the screw connection provides additional stabilization of the tube line in the connection. In addition, the ability to manually retighten the connection makes them more forgiving of minor deviations in the dimensional accuracy of the tubes. The main disadvantage of screw connectors is that most models require additional tools for assembly, which takes time and makes handling more difficult. The same applies to disassembly. If the screw connector is tightened too tightly, the tube line can also be damaged, which in some cases makes it difficult to reuse after disassembly.

Other types of tubing connectors

In addition to the push-in and screw connections described above, there are a wealth of other options for connecting tube lines to each other:

- Clamp connectors: Here, tightness is achieved by pressing a ring.

- Tube nozzles: Simple connectors that are often sealed with a tube clamp.

- Tubing connectors with valves: These allow individual lines to be shut off.

Shapes of tubing connectors

The shape of tubing connectors determines how many lines should arrive at a junction and also how many should leave it again. The following shapes of connectors are common:

- Straight connectors: If you simply want to connect two tubes without the line branching or splitting, straight “normal” connectors are sufficient. As these require little effort in terms of design and manufacture, they are usually cheaper than more complex connectors.

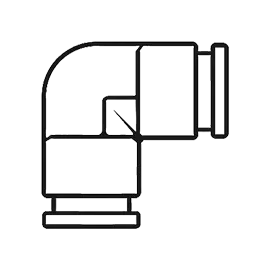

- L-connectors (90 degrees): If a line needs to turn at a right angle, for example along a wall, L-connectors are the right choice. They enable two pieces of tubing to be connected in a clean curve and minimize the risk of kinking compared to laying the line around the curve

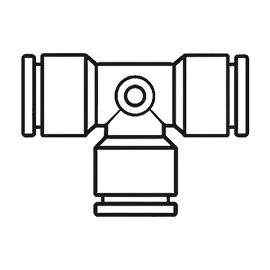

- T-connector: If a main tube needs to be split in two directions, a T-connector is the right choice. This tube connector splits the line into two lines running at right angles.

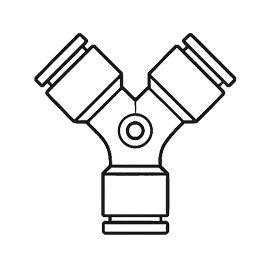

- Y-connector: If a tube line is to be split into two separate lines, but unlike the split using a T-connector, they are to continue in the same direction as before, a Y-connector is the ideal solution. In contrast to the T-connector, the angles of the branches are significantly smaller at 30 to 45 degrees. This also reduces flow resistance, which is particularly important when working with liquids

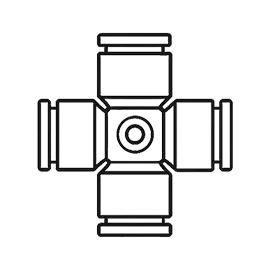

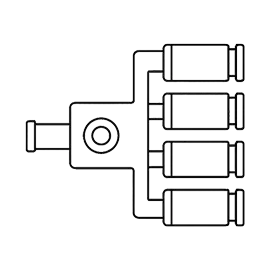

- X connector: X connectors are usually symmetrical with 90-degree angles. They are used when a medium needs to be split centrally into four different directions.

- Multiple distributors: Multiple distributors come into play when a tube line needs to be divided into several lines while maintaining the direction. These allow a tube line to be divided into two, three, four, or even more lines.

L-Connector

T-Connector

Y-Connector

X-Connector

Multiple Distributor

Tubing connectors made of different materials

Different materials are used for tubing connectors depending on the area of application. Various key factors determine which connector is suitable for which requirement. The following factors can be of great importance when selecting the right tube connector:

- Price: Cost-effectiveness is important for all systems – including pipe systems.

- Stability: What pressure must the connector withstand?

- Weight: In many cases, excess weight must be avoided.

- Chemical resistance: What media will the connector come into contact with?

- Formability: How should the system be laid out?

In many cases, compromises have to be made between these factors (there are other factors that are not considered here). For example, connectors with high-pressure stability are often heavier and more expensive. On the other hand, lightweight, inexpensive connectors are often less stable – but more formable. The most common materials for tubing connectors and their advantages and disadvantages are summarized below:

Plastics – lightweight, inexpensive, and versatile

Within the plastics family, there are various materials that can be used for the manufacture of tubing connectors. To list them all here would go beyond the scope of this article. However, here are a few examples:

- Polyamide: This plastic is particularly robust and pressure-resistant, making it suitable for use in pneumatics, where it can withstand standard pressures without any problems.

- Polypropylene: Good resistance to many chemicals, making it particularly suitable for use in laboratory conditions.

- PVC: Particularly inexpensive

In general, plastic tubing connectors are a suitable alternative, especially when the overall system needs to be as light, cost-effective, and flexible as possible. If particularly high-pressure resistance is a basic requirement, metal connectors are usually the better alternative.

Brass – durable and resistant

Brass is an example of a metal that is very well suited for the manufacture of tubing connectors that have to withstand high pressures. In many cases, brass connectors are additionally nickel-plated to minimize surface wear and prevent limescale deposits in applications involving water. Brass is suitable for use with drinking water, in heating systems, and for more complex pneumatic applications. Compared to plastic connectors, however, brass tubing connectors are significantly more expensive, as the raw material is considerably more expensive and the manufacturing process is more complex.

Stainless steel – particularly robust

In terms of price, stainless steel tubing connectors are generally even more expensive than brass ones. Therefore, the use of stainless-steel connectors is particularly useful when the application takes place under truly extreme conditions. These can include particularly high pressures, but also the use of aggressive chemicals. Another area of application in which stainless steel connectors have advantages over brass parts is outdoor applications. Unlike brass parts, stainless steel parts prevent the formation of verdigris.

Aluminum

Aluminum connectors are generally slightly cheaper than stainless steel tubing connectors. However, this is not the only advantage of the material: aluminum is a very light metal and is therefore ideal for lightweight construction applications. In addition, the material is relatively easy to process due to its properties and can therefore be formed into many different and, above all, complex shapes. Aluminum has high compressive strength, even if it is not as high as that of stainless steel. Aluminum also generally lags behind stainless steel in terms of corrosion and chemical resistance

Buy tubing connectors

With so many factors to consider when choosing the right tube connector, it is important to keep track of everything. Poorly prepared purchases can quickly cost many times more in system failures than they initially saved in preparation time. The following questions should be answered in advance for your own application in order to find the right tube connector:

- What pressure must my tube connector withstand?

- What media are passed through my system?

- What environmental influences is my system exposed to?

- How many lines does my system comprise and how should it be laid?

- What is particularly important to me during installation? (Price, durability, speed…)

These five questions and an overview of the type, shape, and materials will help you find the ideal tube connector for your application. However, expert advice can also make the selection process more efficient. PAPUREX, as a manufacturer of polyurethane tubes, works with competent companies that sell tubing connectors and can be found by clicking the button below.

FAQ on tubing connectors

How is tubing connected?

There are various types of connectors to choose from for tubing:

-

- Plug-in connectors: If quick installation is important

- Screw connectors: For high mechanical stress

- Clamp connectors: Achieve tightness through pressing a ring

- Tube nozzles: Simple nozzle – tightness through tube clamp

- Tubing connectors with a valve: Control of single tube lines is possible

Which forms of tubing connectors exist?

The different forms of tubing connectors matter for controlling flow directions:

- Gerade Verbinder – zwei Schläuche werden gerade miteinander verbunden

- L – Verbinder – wenn eine Leitung im 90-Grad-Winkel abbiegen soll

- T – Verbinder – eine Hauptleitung wird in zwei Richtungen aufgeteilt

- Y – Verbinder – Aufteilung auf zwei Leitungen in der gleichen Flussrichtung

- X – Verbinder – Eine Leitung wird zentral in mehrere Richtungen aufgeteilt

- Mehrfachverteiler – Eine Leitung wird auf mehrere gesplittet, die Richtung bleibt gleich

How do you install a tubing connector?

How a tubing connector is installed depends on the type of connector. The simplest way is a plug-in connection. As the name suggests, you can simply plug the tubes into the connector. In the case of high-quality plug-in connectors, the lines can be separated again, and the connectors can be reused.

If a more stable connection is needed, a screw connector is the best choice. In this case, a cap nut gets placed on the tube. After that, the connector is fitted to the tube and screwed with the cap nut.

What is the difference between tube fittings and connectors?

In practice, the terms fitting and connector are used as synonyms. Hence, there is no clearly defined difference between a tube fitting and a tube connector.

What is the strongest type of tubing connector?

For very high pressures, metal tubing connectors are the best choice. For a maximally stable connection, permanent grouting is the way to go.

Any questions?

Don’t hesitate to give us a call – we are happy to advise you.