Production waste becomes regranulate

The extrusion of polyurethane tubing inevitably produces waste. The reason for this lies in the manufacturing process itself. The machines (extruders) have to be started up slowly at the beginning of production. The polyurethane that passes through the extruder during this time does not yet come out of the extruder as a finished tubing item. First, the production temperatures and dimensional properties of the Tubing must be adjusted. In the past, PAPUREX collected this material and sent it to an external processor for recycling. Since 2021, however, the plastic waste generated in this way has been recycled directly on site. The material produced in this recycling process is called regranulate.

The importance of regranulate for the environment

Plastic waste is a huge problem worldwide. Even with consistent waste separation, a large proportion of plastic waste in Germany is still not recycled, as current figures from the Federal Environment Agency show. Around 60% of plastic waste is still “energy recovered,” i.e., incinerated. This generates electricity and heat, but at the cost of releasing a considerable amount of greenhouse gases. It is much more efficient to use plastic waste for its original purpose. In the case of PAPUREX, this is polyurethane tubing.

However, the production of regranulate from production waste not only avoids greenhouse gas emissions by not having to incinerate it as plastic waste. Another advantage of using regranulate for the product it was originally intended for is that it replaces new material. The production of plastics also generates a large amount of greenhouse gases. In the case of polyurethane, for example, this amounts to between 3.5 kg and 5 kg of CO₂ for every kg of material produced. If regranulate is now used for the manufacture of the end product, these emissions can be completely avoided.

In this way, around 350 tons of CO₂ have been avoided in the production of PAPUREX alone over the last four years. To put this into perspective: a car that consumes 6 liters of gasoline per 100 km emits around 145 grams of CO₂ per kilometer driven. With the 350 tons of emissions avoided, this car could travel 2,413,793 km. That is equivalent to around 60 trips around the equator.

Regranulate at PAPUREX – step by step

A lot has changed since the first experiments with regranulate. This was necessary because processing recycled production waste is not as easy as it sounds. Since the polyurethane has already been processed (thermally broken down) once, its properties differ from those of “new” material. Consequently, many trials had to be carried out with regranulate to find out how much could be incorporated into which tubing without impairing its key properties.

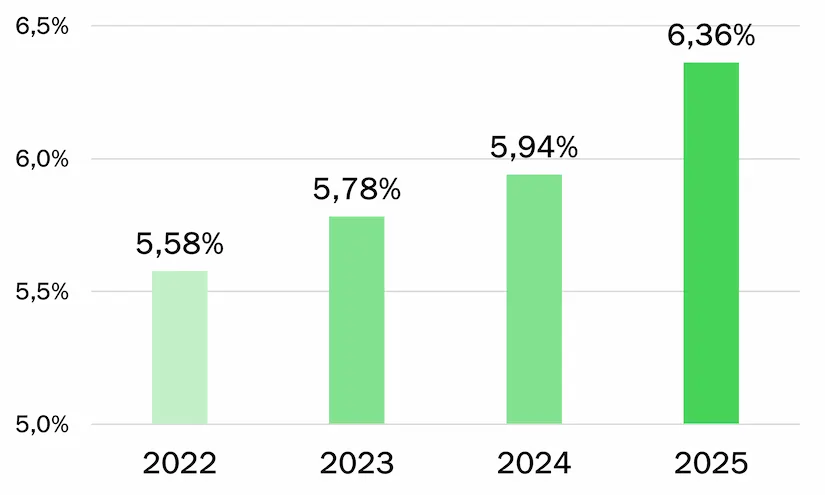

Accordingly, it was a real milestone at the end of 2025 when the first PAPUREX tubing made from 100% recycled production waste was manufactured. A genuine regranulate tube, in other words. These gradual developments have led to a steady increase in the proportion of regranulate in the total processed material in recent years. From a good 5.6% in 2022, it rose incrementally to 6.36% in 2025. That may not sound like much at first, but it corresponds to several tons of polyurethane.

The aim for the coming years is to further increase this proportion. However, the proportion of reprocessed production waste cannot be increased indefinitely. The first step is to have production waste. Even better than producing and reusing regranulates is to avoid production waste in the first place. And here, too, PAPUREX is working to achieve improvements through continuous development. You can find more background information on the topic of the environment at PAPUREX in our environmental statement. The current edition can be downloaded using the button below this report.