The long road to CO2-neutral production

Achieving CO2-neutral production in Scope 1 and 2 by 2025 was already the ambitious goal set out in our first environmental statement, published in 2021. Over the last few years, this goal has come within reach, and on October 31, 2025, it was achieved. However, to understand what CO2 neutrality and the scopes are all about, we need to go back a little further.

The conversion of tubing production in Mörlenbach to reduce emissions began back in 2003. Long-time managing director Rudolf Biebl anchored the issue of environmental friendliness in PAPUREX’s DNA – long before it became a buzzword. In 2003, the switch to pure green electricity was a major step toward CO2-neutral production. Several hundred megawatt hours of electricity are consumed annually at the production site in Mörlenbach. For this reason, the switch to green electricity was particularly important for PAPUREX. This has already prevented several thousand tons of CO₂ emissions since 2003. Further background information on this can be found in our environmental statement, which is available for download in the Environment section.

Is PAPUREX’s production now completely CO2 neutral?

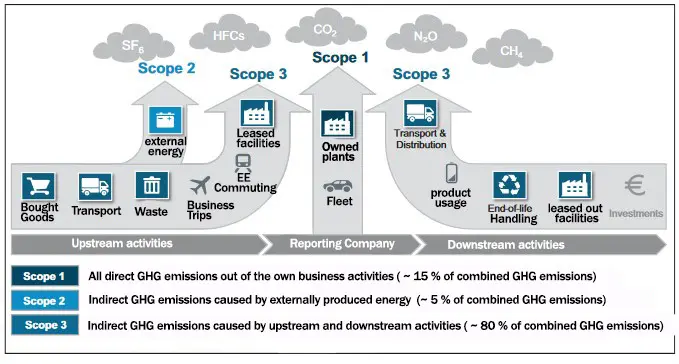

To answer the question in advance: No, it is not. It must be emphasized that CO2-neutral production only refers to Scopes 1 and 2. A detailed explanation of the scopes can also be found in our environmental statement. The most important points are summarized below:

Scope 1 covers all direct emissions from sources owned or directly controlled by a company. These include, for example:

- Stationary combustion (heating oil, generators, local energy production, etc.)

- Mobile combustion (company cars, industrial trucks, trucks, etc.)

- Industrial processes (emissions during processing)

Scope 2 includes all indirect emissions resulting from the purchase of external energy. This could apply, for example, to the following energy sources:

- Electricity

- District heating

- Steam

Scope 3 encompasses what is probably the largest share of emissions generated by a company’s business activities. These are indirect emissions that are not directly influenced by the company. Examples of this are:

- Emissions from the purchase of goods

- Transport of goods

- Emissions from the disposal of manufactured products

To return to the original question: PAPUREX production is only CO2 neutral within the first two scopes. This means that all direct emissions and those caused by the purchase of external energy have already been reduced to zero. However, there is still work to be done in Scope 3. The largest emission factor at present is the procurement of polyurethane, the raw material used in PAPUREX tubing. Here, it is important to work closely with suppliers to reduce Scope 3 emissions. Promising alternatives have already been announced, which PAPUREX will evaluate on its way to completely CO₂-neutral production.

Current steps towards CO2-neutral production

In addition to the first steps taken more than 20 years ago, PAPUREX has recently made significant progress towards CO2-neutral production. In March 2025, the first part of the new heating system went into operation. This replaced the old oil heating system and eliminated a major source of CO2 emissions. At the beginning of November, the second part of the new heating system was finally put into operation. It consists of an air and a brine heat pump. The latter was recently put into operation after lengthy installation work. This means that the CO2-neutral heating system is ready for the coming winter.

An additional hurdle that was completely overcome at the end of October 2025 is the electrification of the PAPUREX company fleet. The first fully electric company vehicle was added to the PAPUREX fleet back in 2019. Since then, more and more electric drives have been integrated into the fleet, initially via the intermediate step of hybrid technology. This process did not stop at the in-house forklift truck, which was converted from diesel to electric drive in 2021. Last October, the last lease on a vehicle with a combustion engine (it was already a hybrid) came to an end. In line with company policy, this was replaced by an electric vehicle. However, there is no sign of range anxiety in the PAPUREX team. By October of last year, colleagues were already genuine fans of electric cars, as can be read in the interview on the subject of electric cars.

This means that CO2-neutral production in the first two scopes is now a reality for PAPUREX and the ambitious goal of just-in-time has been achieved. However, as previously indicated, a new task begins where the old one ends. The big goal now will be to reduce Scope 3 emissions step by step. Unlike the first two tasks, however, this will require a joint effort, for which PAPUREX will work closely with all parties involved in the polyurethane tube value chain.